Overview of the types of products offered in the Iteco Washing Systems range.

The vehicle washing systems sector offers a wide range of cleaning equipment Each system is different and designed to meet the specific logistical and financial needs of each company.

This page provides an overview of the categories of products offered by the Iteco Washing Systems range.

This self-propelled washing equipment on wheels has a single brush. These systems have a drive that facilitates manual movement of the system by the operator.

Their cleaning system can cover the entire outer surface of the vehicle being washed thanks to their tilting system. They can clean surfaces sloped to a maximum of 20°.

This segment of the range is the most economical of the Iteco Washing Systems line, however it offers the same performance as the bigger washing systems such as the brush rollover systems and drive through systems.

This category is designed to meet small/medium sized company needs without forecourts to park and service the vehicles.

Demonstration videos

The brush rollover washing systems are self-propelled systems for external cleaning of vehicles.

The washing system of this machinery is self-propelled. During cleaning operations, the vehicle remains still while the system independently executes the entire washing program.

The brush rollover systems have many accessories. In every installation, the number of washing brushes varies from a minimum number of two to a maximum of five units and avails of additional double front and rear brushes with a “mirror saving” program, for accurate washing without damaging rear view mirrors.

The washing systems are ideal to meet the typical needs of small/medium sized transport companies.

Demonstration videos

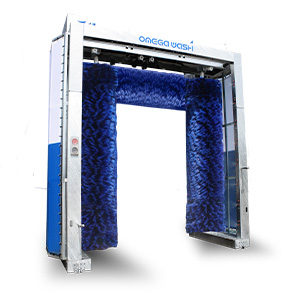

Automated washing systems with fixed structure to install in the space intended for washing vehicles.

Drive through washing systems are a range of products that avail of an assortment of additional accessories to optimise the vehicle cleaning process.

The washing cycle is activated by a mechanical sensor on the ground or photocells. When the vehicle continues through the tunnel, the brushes to the side, horizontal and pre-washing arch brushes activate (according to the model) moved by independent pneumatic cycles or by electric motors controlled by the PLC and finishes with the rinsing arch.

Equipped with a pressure control process of the brushes, the drive through washing systems enable an extremely fast washing cycle, offering unbeatable washing quality.

The drive through washing systems meet the typical needs of small/medium sized transport companies.

Demonstration videos

To eliminate tar and dirt sediment accumulated during vehicle travel, the under chassis washing systems are ideal for cleaning underneath the chassis and body.

The washing system is installed underground, composed of a nozzles system that sprays high pressure water. Under chassis washing was designed to guarantee efficient cleaning in sections of difficult to clean vehicles.

This washing system can be integrated with the drive through and brush rollover systems.

Demonstration videos

The equipment guarantees the complete and professional sanification of vehicles (cars, trucks and buses), offices, civilian and industrial enclosed areas.

Ozone-O3 can remove virus, bacteria, polluting agents, and bad odours.

The device is equipped with an ozone generator, for the disinfection of the air present in an environment, and a nebulization system, capable of introducing into the environment a disinfectant solution necessary to sanitize even hard surfaces.

Managed by an Android app via Bluetooth, it allows you to control its operation remotely.

Demonstration videos

As well as designing the washing systems, Iteco Washing Systems offers consultancy by its experts to set up the various types of systems for purification and treatment of wastewater used during the washing cycles of the systems.

Together with the cleaning systems, we also offer cleaning product samples to test. Every detergent has its own specific function for use in vehicle cleaning.