Guide to sanitizing vehicles with the Ozone-O3 multi-sanitizing station.

With the Covid-19 virus pandemic, sanitation and disinfection procedures have become essential to safeguard the health of people in public environments.

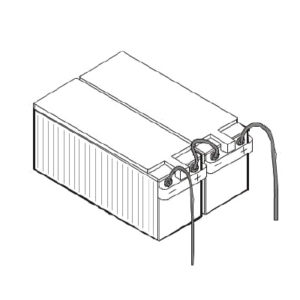

The new Ozone O3 multi-sanitizing station has recently been added to our product range, a device designed for the sanitization of transport vehicles such as trucks, buses and building spaces from 150 to 300 m2 equipped with a ozone generator and a nebulization system.

In this article, a guide to sanitizing vehicles with our sanitizing station will be illustrated step by step, with useful tips and warnings for a correct, professional and safe sanitation.

1) Preparation for sanitation

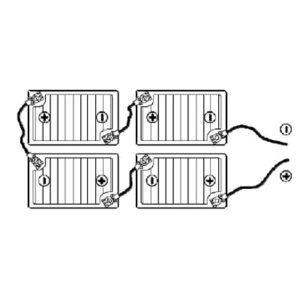

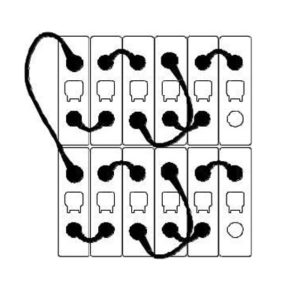

Remove any objects inside the vehicle and close all windows and doors. Place the station on the floor as close as possible to the air intake of the ventilation system.

Unscrew the cap located on the top of the Ozone-O3 and enter the amount of sanitizer as indicated in the table in the “usage and maintenance” manual supplied with the machine.

Connect the station to a power supply, if you need to sanitize a room, you can use the adapter for 220 V wall sockets.

Start the vehicle with the handbrake engaged and set the ventilation system to “air intake from outside”, with minimum temperature (16 °C), fan at minimum speed, uniform air distribution on all air vents and air conditioning switched on.

2) Setting the sanitation program

Before proceeding with sanitization it is important to remove people and animals from the area intended for sanitation, because ozone is harmful.

Minimum inhalation: Respiratory problems, itchy eyes;

Prolonged inhalation: Sense of suffocation, possible pulmonary edema, nausea, vomiting and loss of consciousness and a state of coma in humans after one hour of continuous exposure.

It is important to inform the staff present and close any access points to the area.

Once the area has been made safe, it is possible to set the most suitable program for the area to be sanitized (cars, trucks, buses, 150 or 300 m3 rooms) via Air-O3, the Android smartphone application managed with the phone’s Bluetooth system.

Sanitation with the Ozone-O3 station is divided into two phases: ozonation and nebulization. In both phases it is possible to set the processing times, the cycle start time or choose whether to process only the ozone cycle or the nebulization cycle.

Sanitation setting only ozone cycle.

Sanitization setting only nebulization cycle

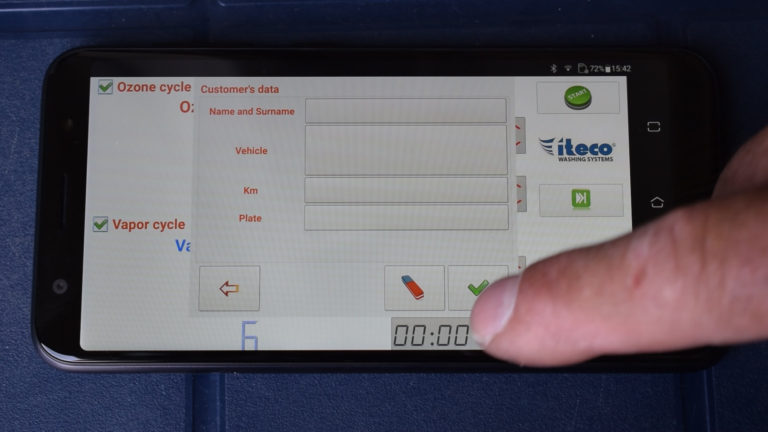

Select the “Start” button, a window will appear in which to enter the data of the vehicle to be sanitized which will be shown in the certificate of successful sanitation.

Click on the “Check” button to start the sanitization cycle.

Warning: When the sanitation process begins, a safety beeper is activated which has the purpose of alerting people in the vicinity of the sanitation in progress.

3) Post-sanitization operations

Select the “Start” button, a window will appear in which to enter the data of the vehicle to be sanitized which will be shown in the certificate of successful sanitation.

Click on the “Check” button to start the sanitization cycle.

4) Print certificate of successful sanitation

The smartphone application also has a section dedicated to printing the certificates of successful sanitation of the treated areas.

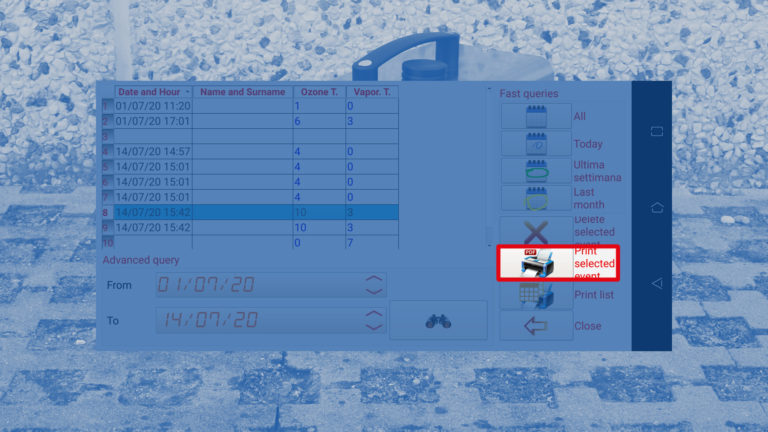

Confirm the print.

Finally, a pdf file will be exported with the transcription of the times and the data previously entered at the time of starting the sanitation cycle to be shown in case of checks.

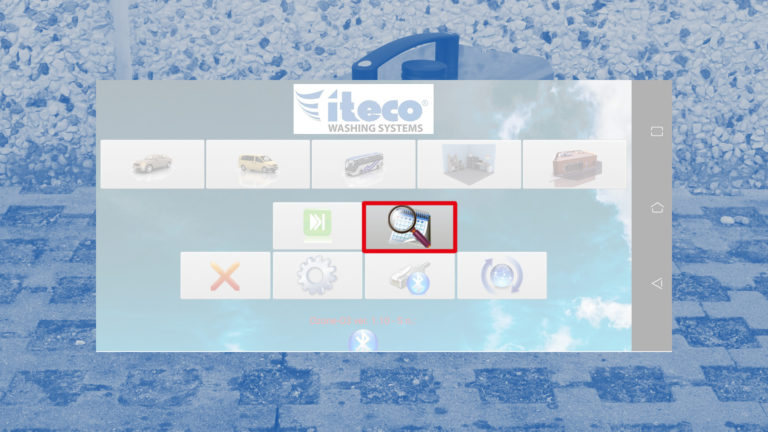

Select the icon for printing certificates.

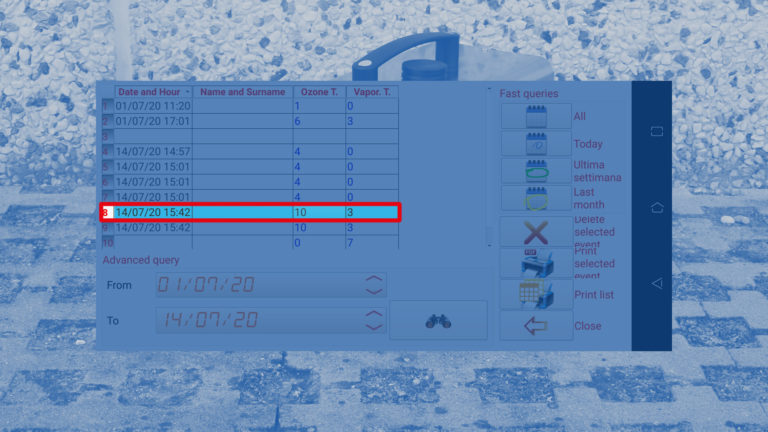

Select the sanitizing cycle to be printed in the table.

For more details and information on the Ozone-O3 Multi-Sanitizing Station: